LATEST NEWS

Tel: 18588627858

Hicaree Refrigerator Production Line Intelligent Upgrade Project

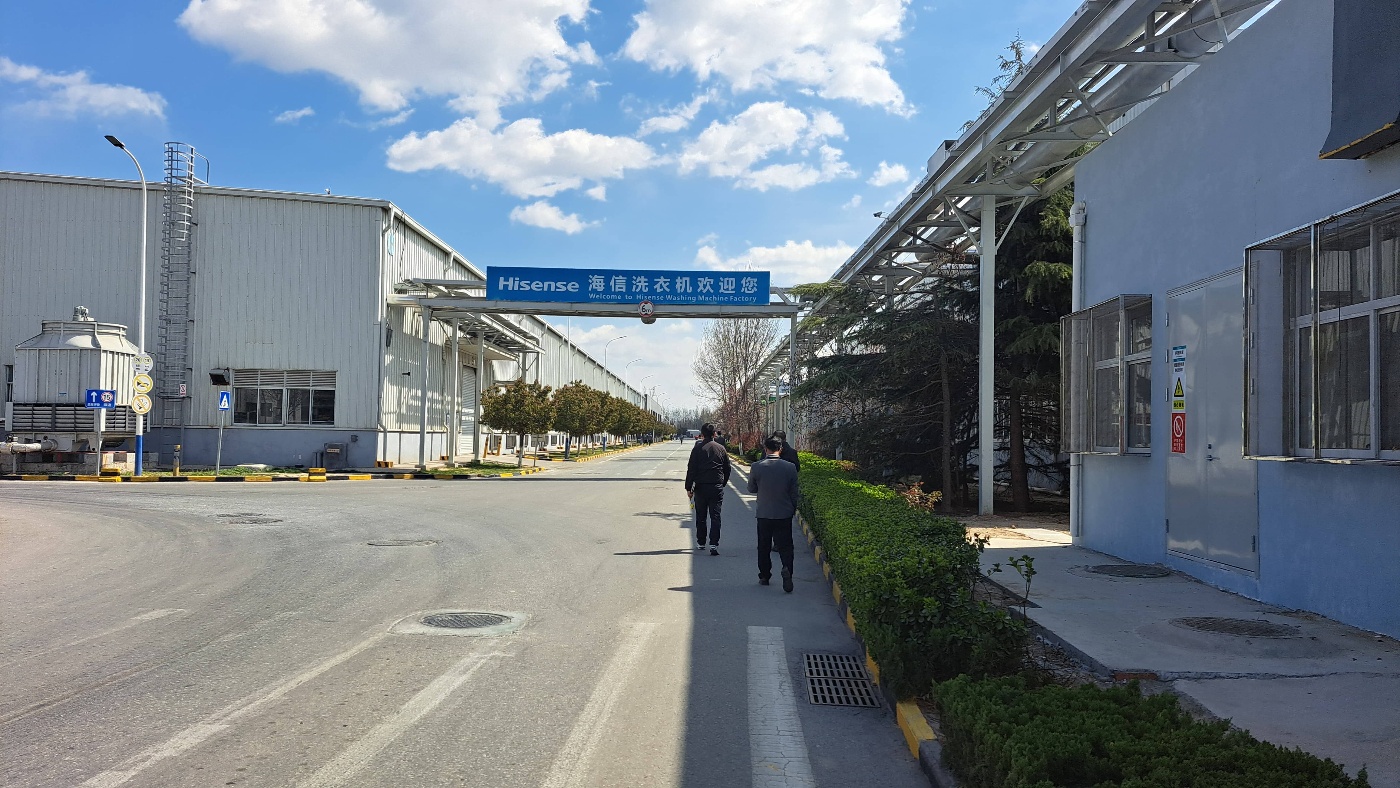

Hisense Refrigerator Production Line Intelligent Upgrade Project

As a core supplier of refrigerator production lines, our company has reached a strategic cooperation with the well-known home appliance brand Hisense to provide them with a complete set of intelligent production line solutions. The project aims to assist customers in achieving production capacity upgrades, quality optimization, and energy-saving goals through technological innovation and efficient production systems.

Solution:

1. Customized production line design

Based on the characteristics of Hisense products, our company designs modular assembly lines that are compatible with the production of multiple models of refrigerators, reducing changeover time by 40%.

Integrate high-precision robotic arms and automated conveying systems, achieving 100% automation of key processes such as door assembly and foam injection.

2. Silencing and Energy Efficiency Technology Empowerment

By using our patented sound insulation materials and low friction transmission components, the noise level of the production line has been reduced to below 70 decibels, and the operation of the finished refrigerator has reached an industry-leading level of quietness.

Implant an intelligent energy consumption monitoring system to optimize equipment power consumption in real-time.

3. Digital Quality Management

Deploying our independently developed AI visual inspection system, the defect recognition accuracy exceeds 99.5%, significantly reducing the rework rate.

Production data is synchronized in the cloud, and customers can track progress and quality control reports in real-time through mobile devices.

Project achievements:

Efficiency improvement: The daily production capacity of a single line can reach 1200 units, and the delivery cycle is shortened by 30%.

Sustainability: The production line has obtained ISO14001 environmental protection system certification, and the waste recycling rate has been increased to 90%.

Our Value:

As a leading intelligent equipment supplier in the industry, our company always puts customer needs at the core and provides full lifecycle services from design, manufacturing to operation and maintenance. This case once again validates our company's innovative strength and delivery reliability in the field of refrigerator production lines.